Library Preparation for NGS Practical Application Challenges | NGS Library Preparation Workstation Auto-NGS 100R

In 2002, after the SARS epidemic broke out, it took 5 months from when the first case was reported in Foshan, Guangdong in November to the final identification of the pathogen SARS coronavirus in April of the following year.

At the end of 2019, another epidemic ravaged the world. This time, it took only a few days for the Chinese team of scientists to locate the "real culprit" - the new coronavirus (SARS-CoV-2), and published the whole genome sequence of the virus for the first time, winning precious time for the global fight against the epidemic.

This is a story of technology benefiting mankind, and the protagonist behind the story is Next Generation Sequencing (NGS).

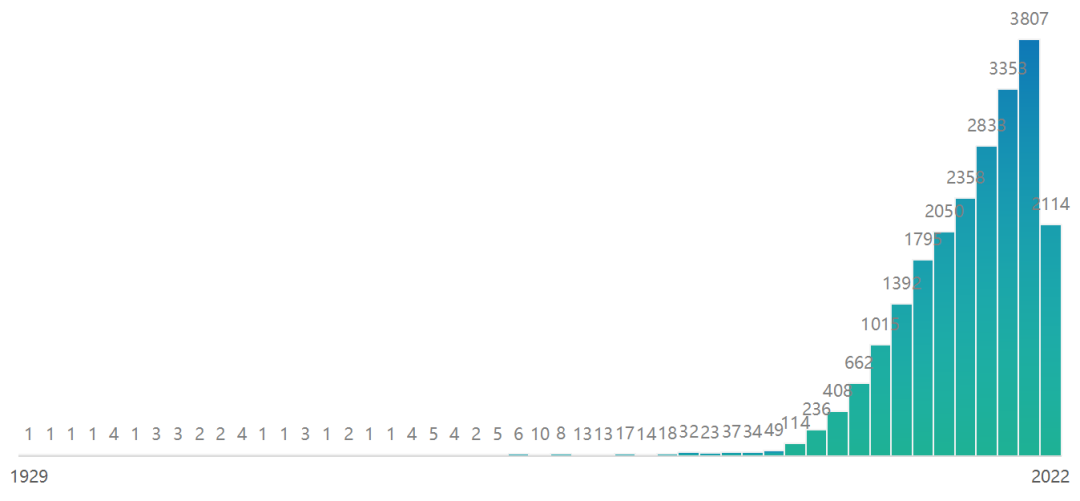

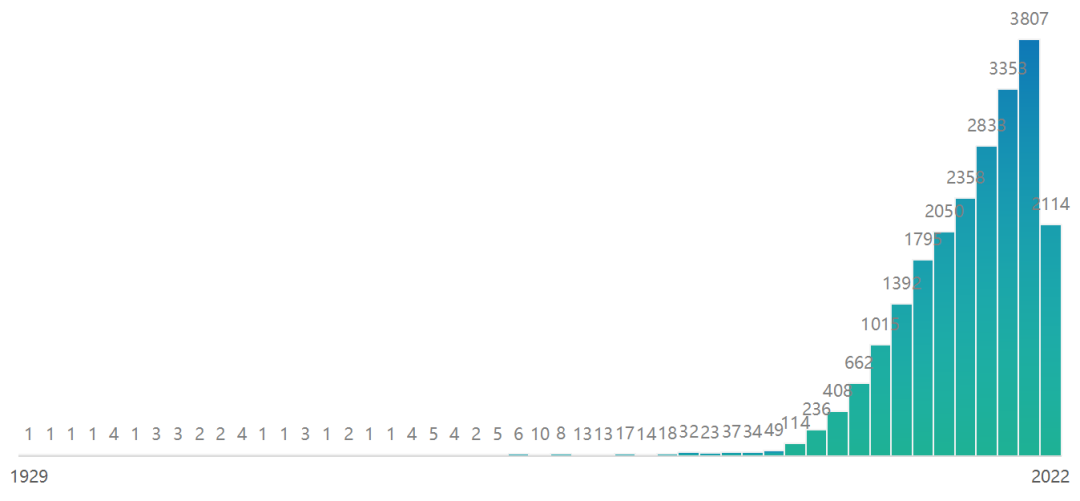

As an important part of modern biotechnology, the application of NGS is getting wider and wider. Searching with NGS as the title keyword can see that related research papers are also increasing year by year (Figure 1).

Figure 1: Number of NGS-related Research Studies

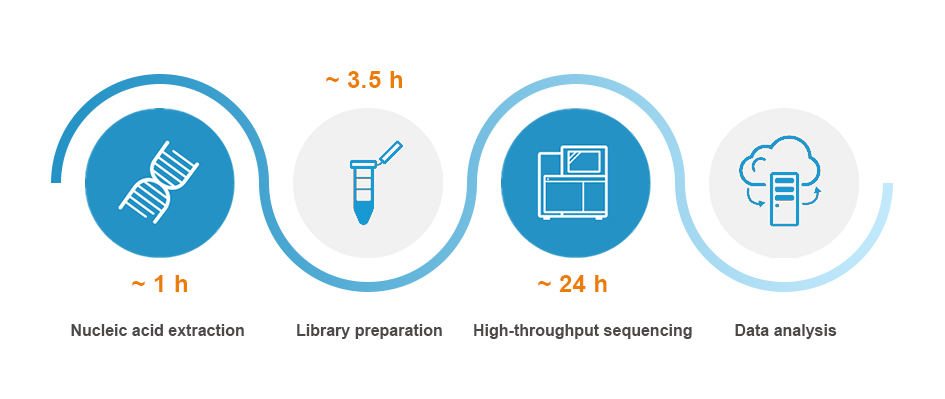

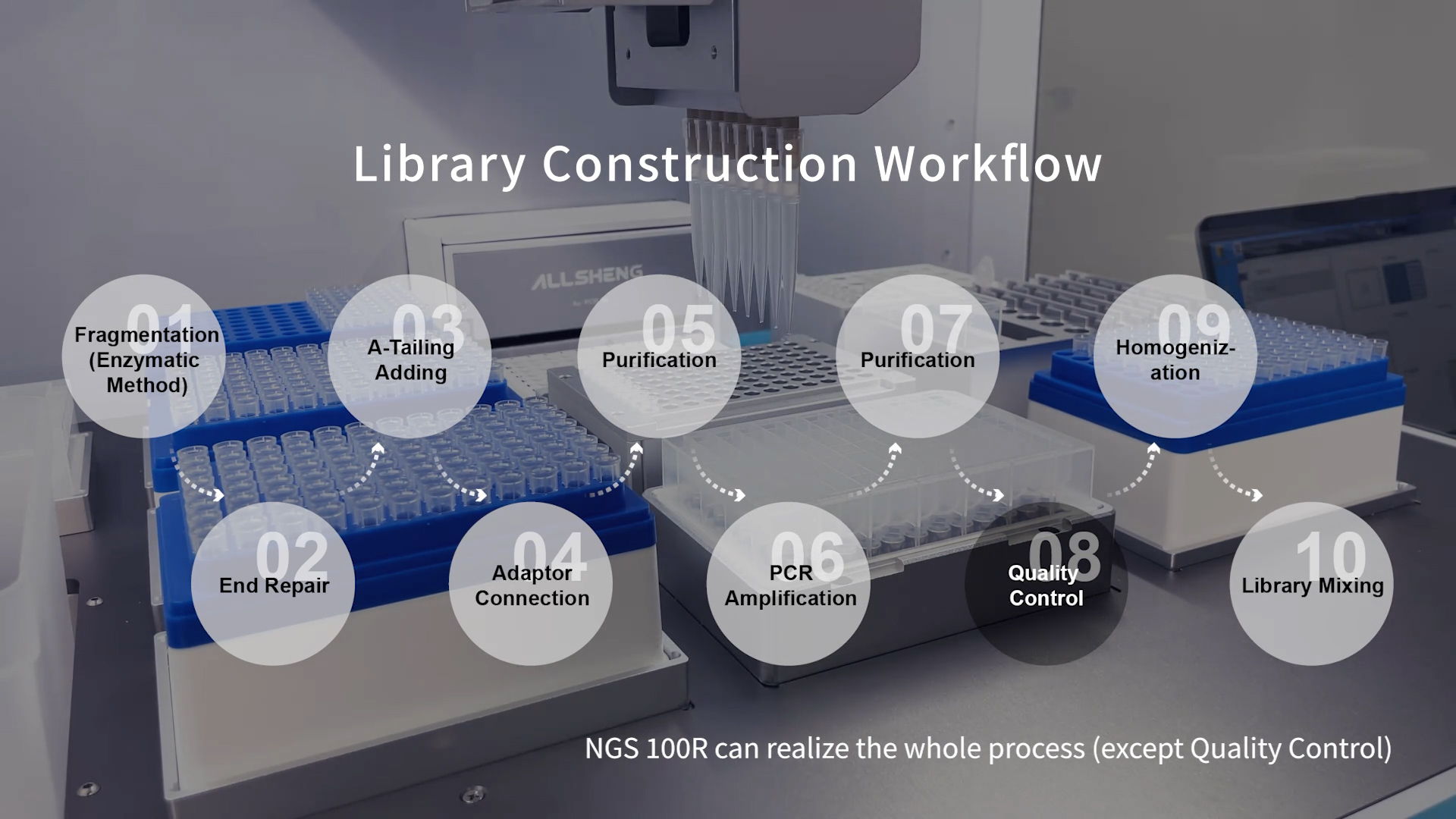

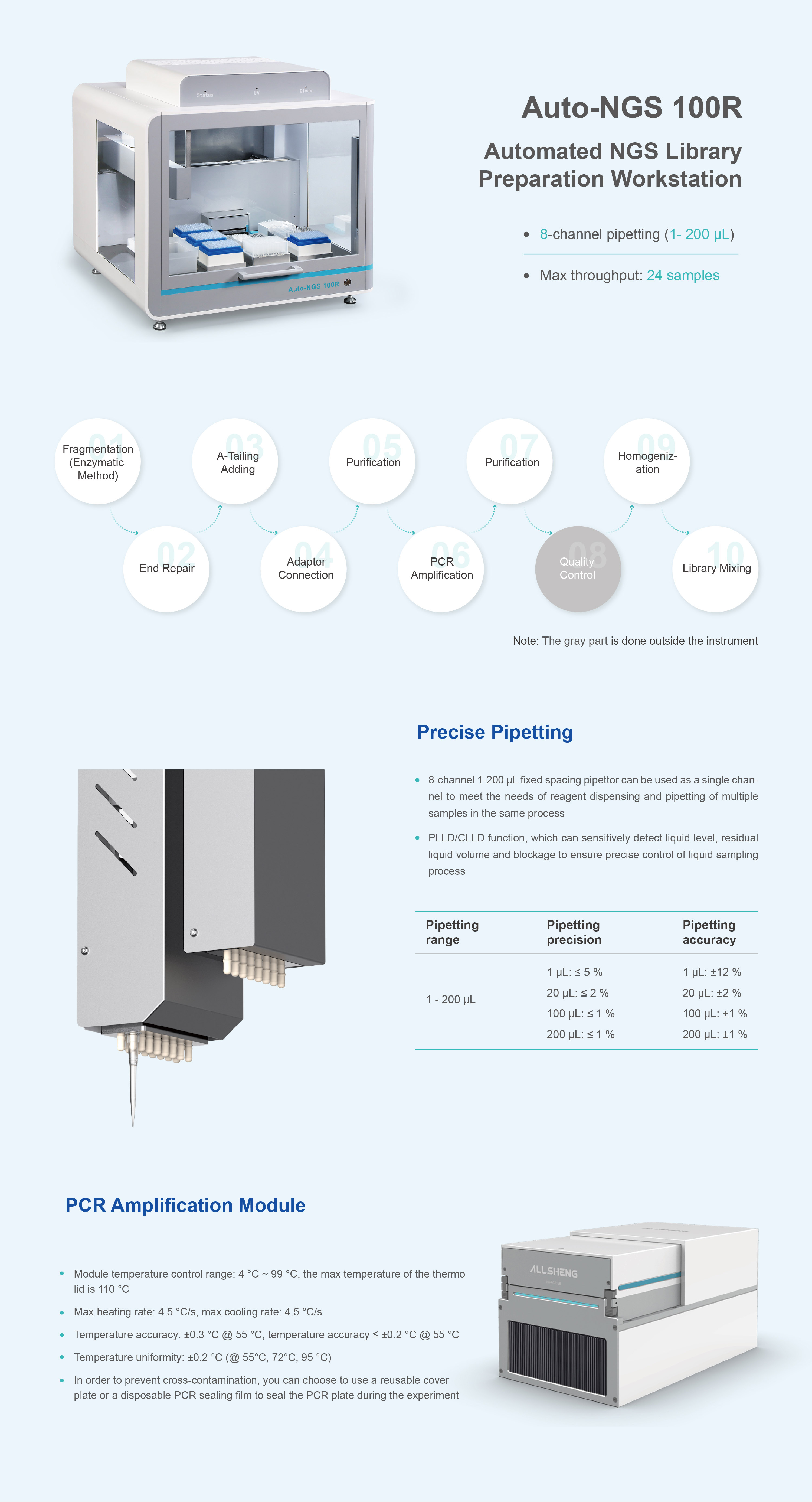

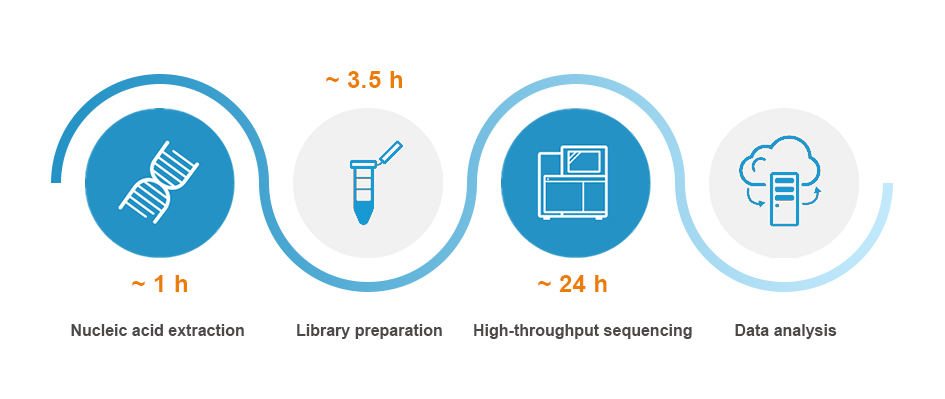

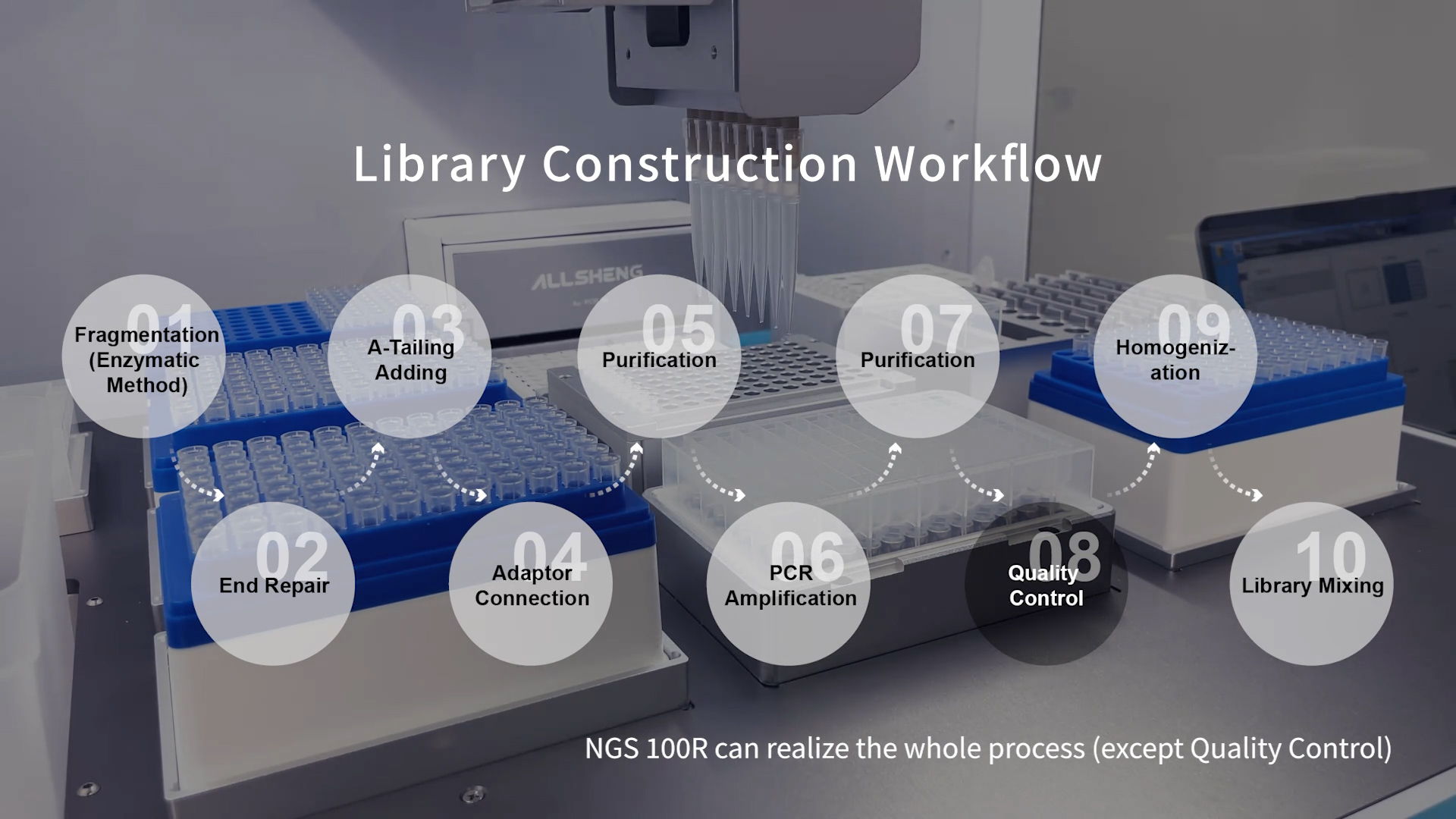

With the vigorous development of NGS technology, the overall experimental process takes a long time (Figure 2), and the library preparation process is complicated (Figure 3), which has become a problem that puzzles everyone.

Figure 2: Basic Flow of Sequencing

Figure 3: DNA Library Construction Workflow

Library preparation is a very critical part of the NGS experimental process. If a lab needs to process hundreds or thousands of library samples, time-consuming manual processing can become a disaster when manpower is limited. Large sample volumes, poor reproducibility, manual handling errors, and inconsistent batches all result in higher costs and longer cycle times.

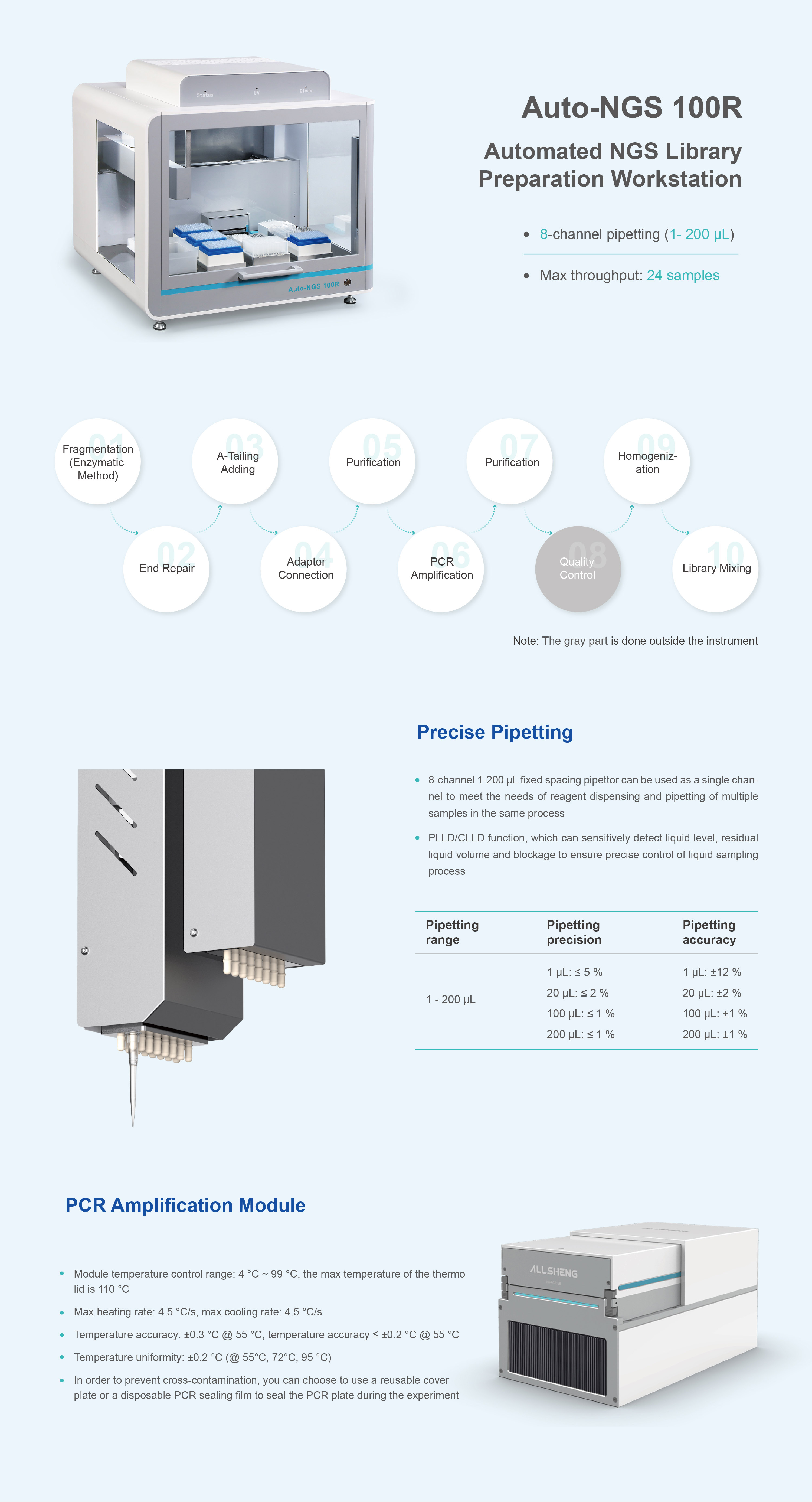

With the continuous requirements of automation, more and more automated instrument manufacturers have introduced liquid handling workstations that are adapted to the automated library preparation process. However, this library preparation liquid handling workstation is often under the framework of the existing liquid handling workstations. Integrate various functional modules such as temperature control module, amplification module, mixing module, and magnetic plate module to realize the automation of library construction. However, because it was born out of a large-scale liquid handling workstation, the platform is often too large to be suitable for small batch experiments, and the operating software is complicated, and the program needs to be edited in the form of programming. Therefore, it is difficult for this kind of library preparation liquid handling workstation to achieve better flexibility and match the actual needs of a variety of library preparation kits on the client side.

In addition, there is also a type of single-sample closed library preparation platform on the market. The instrument has built-in temperature control module, pipetting module and other functional modules, and the reagent cartridge with pre-packaged reagents can quickly complete a single-sample library preparation. The biggest advantage of the single-sample closed library preparation platform is that it is easy to operate, only the process of sample addition is manual operation, and the occurrence of cross-contamination is effectively avoided. However, the problems of such instruments are also obvious. Only one sample library can be constructed at a time, which cannot meet the needs of large sample library preparation.

Auto-NGS 100R is a fully automated, high-throughput system specially designed and developed for library preparation, which can meet the simultaneous preparation of 24 sample libraries at one time. The library product can be obtained in a short time only by putting in the prepared nucleic acid. While improving efficiency, it also guarantees the accuracy and batch stability of the samples. Operating software graphical design and clear operation logic, greatly reduce the difficulty of use.

Differences Between Manual Preparation and Workstation Preparation

Method | Manual Preparation | Auto-NGS 100R |

Time | 8 libraries can be prepared in 8h | Reagents and program can be prepared in 20 minutes, and 24 libraries can be prepared in about 3.5 hours |

Processing throughput | Ideally, about 8 samples can be processed in a day | 1-24 samples can be prepared in one run without any need for attendance |

Reliability | Results are highly variable | Increased repeatability |

Cost-effectiveness | Errors due to manual preparation waste time and resources | Reduce the probability of waste of reagents and samples |

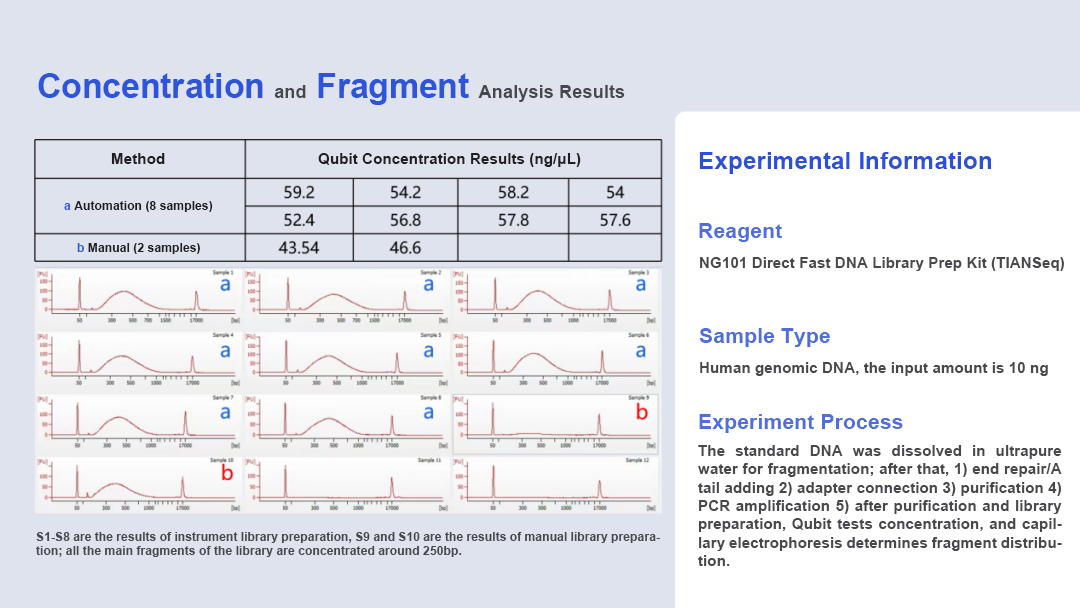

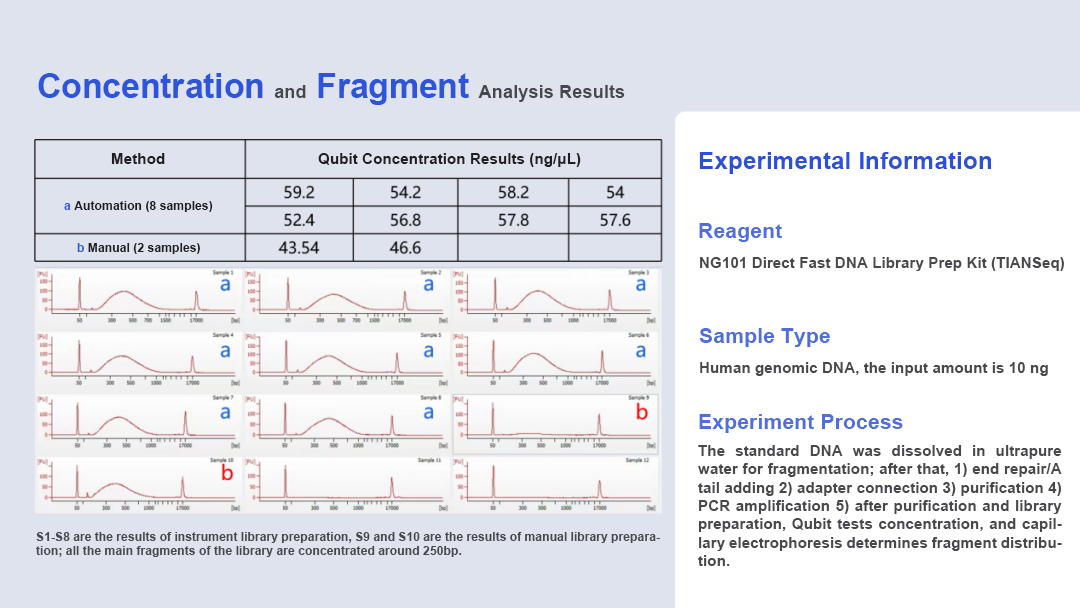

Using Auto-NGS 100R preparation, it only takes about 20 minutes of manual intervention for consumables loading, reagent preparation and library preparation. Compared with traditional manual preparation, it not only improves the efficiency, but also achieves better results (Figure 4).

Figure 4: Concentration and Fragment Analysis Based on Manual and Automated Preparation

Note: Relevant experimental data come from Allsheng laboratory

Special Attention

Allsheng will bring Auto-NGS 100R to RHD 2022 2nd Genetic and Reproductive Testing Technology Innovation Forum.

Booth number: A7, welcome to visit!

Biological Sample Preparation

Biological Sample Preparation

Life Science Detection Products

Life Science Detection Products

POCT Detection & Reagent

POCT Detection & Reagent

Automation & Liquid Handling

Automation & Liquid Handling

Laboratory Instrument

Laboratory Instrument

Reagent & Consumable

Reagent & Consumable

Others

Others

OEM/ODM

OEM/ODM

Release time:2022-08-29

Release time:2022-08-29

Source:

Source:

Pageviews:3583

Pageviews:3583

+ 86 571-88859758

+ 86 571-88859758 sales@allsheng.com

sales@allsheng.com