Application of Liquid Handling Workstation in Cell Level High-Throughput Drug Screening

High throughput screening (HTS) is a technical method for evaluating the pharmacological activity of a large number of samples in order to search for new drug leads. The HTS technology system integrates multiple technologies to achieve rapid, efficient, microscale, automated, and large-scale drug screening. It is an important technical method for new drug research and development.

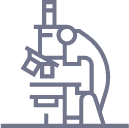

The entire process of high-throughput drug screening requires requires a large number of compounds with pharmacological activities for horizontal comparison. Cell level drug screening is a drug screening model that is closer to physiological conditions. It takes the whole cell as the object of drug action, observes the impact of drugs on the whole cell, and can fully reflect the comprehensive effect of drugs on cells and organelles, resulting in higher screening accuracy.

Based on the overall level of cells, drug screening can not only examine the effectiveness of drugs and clarify their targets, but also obtain kinetic parameters such as drug transport, retention, and metabolism in vivo through the characteristics of cell proliferation, decay, and changes in the intracellular and extracellular environments. It has the characteristics of trace, accurate and stable, and is currently a mature and widely used method.

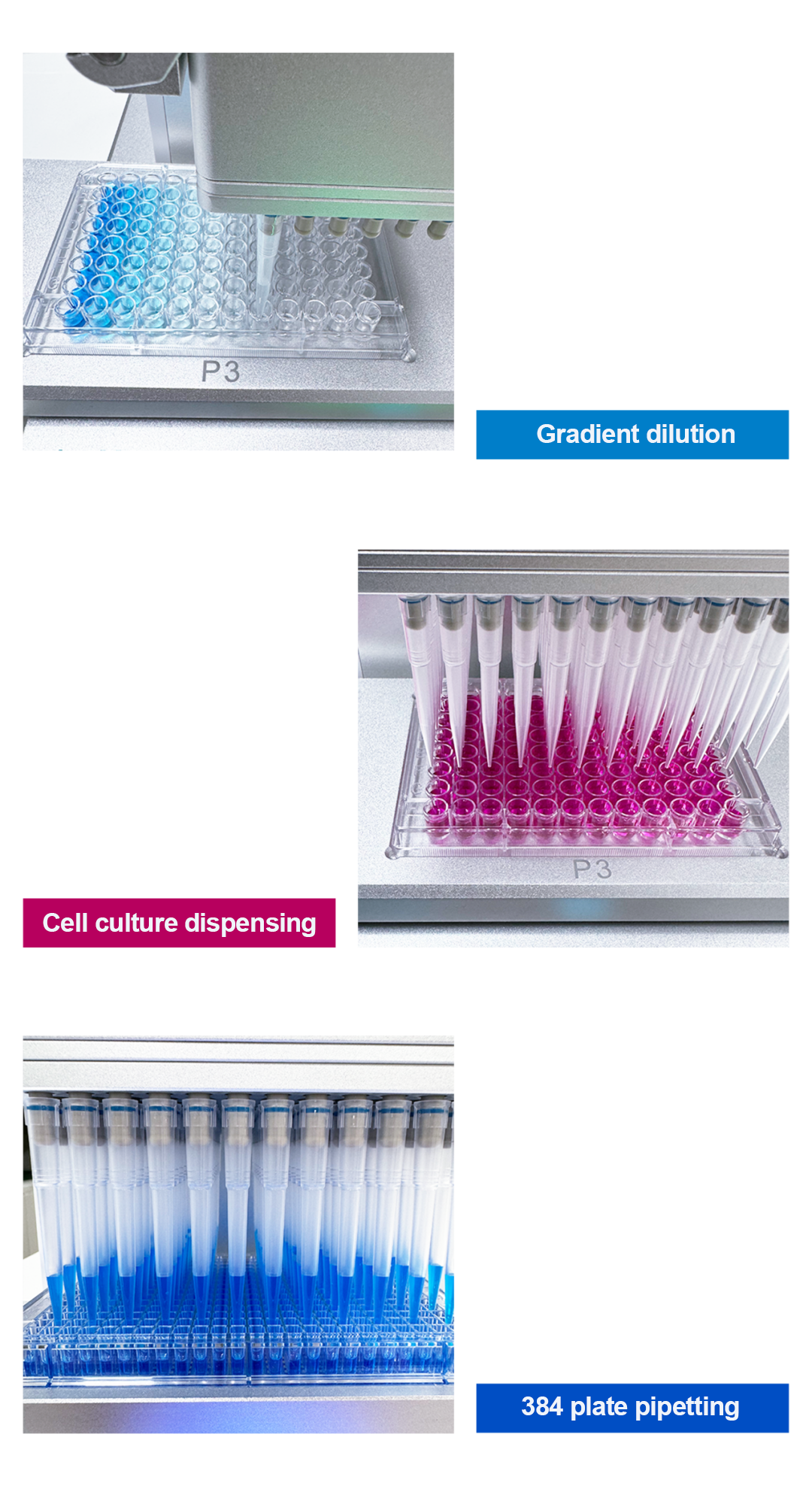

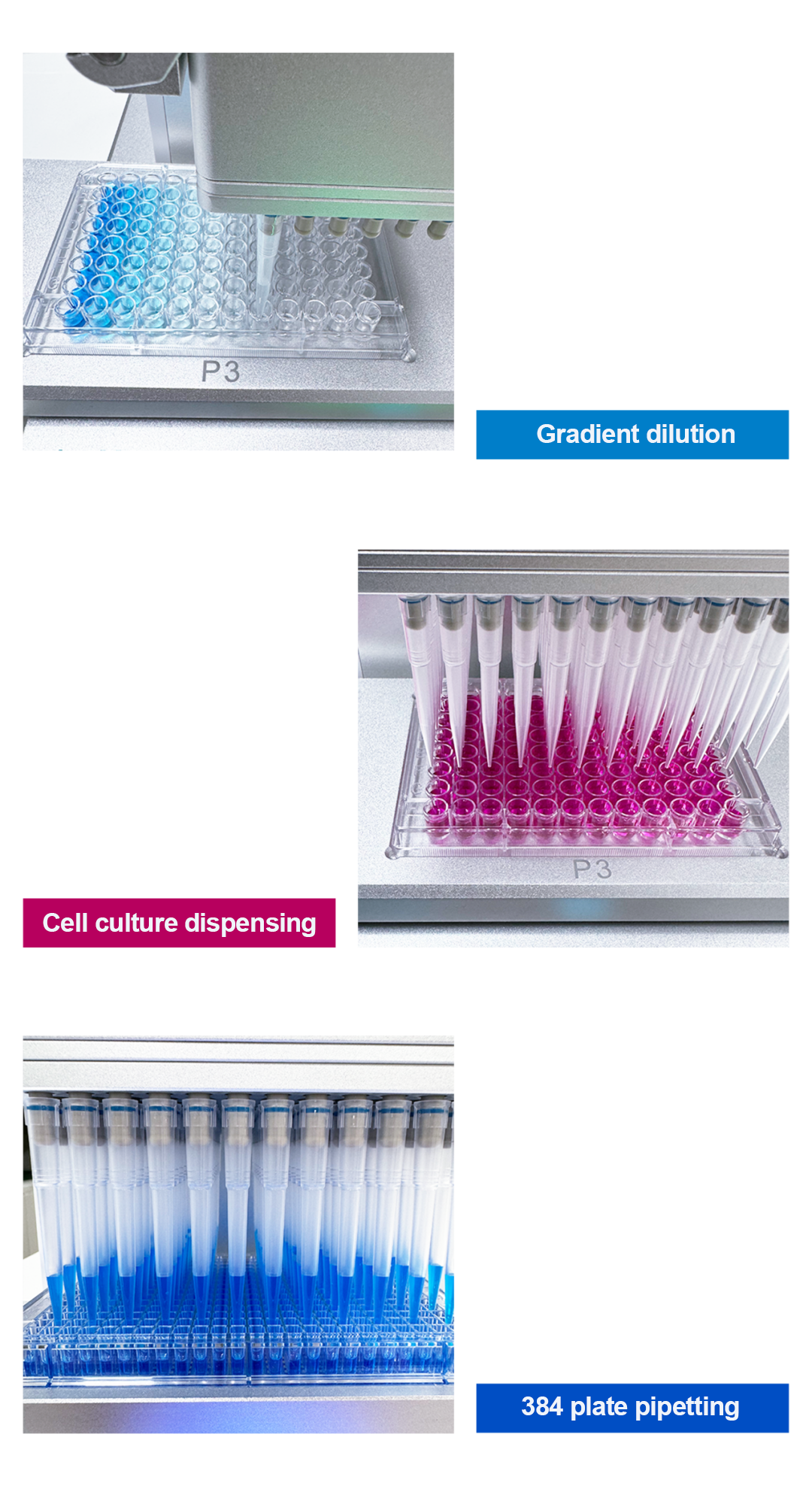

In the long drug screening cycle, a large number of repetitive and cumbersome pipetting operations are often required, such as medium allocation, cell suspension transfer, drug gradient dilution, and drug distribution to cell culture systems with different concentrations, as well as various detection reagent transfer treatments. One of the main reasons for the failure of high-throughput drug screening tests is the large volume span, large workload, and high requirements for repeatability, as well as the incorrect pipetting steps. Thanks to the rapid development of automated liquid handling workstations, there are better solutions to this problem.

Accuracy and precision are indicators used to evaluate the performance of pipettors. The average of multiple measured values at the measurement point is taken, and the degree of deviation between the average value and the target value is called accuracy; the degree of deviation between multiple measured values of measuring points is called precision. The precision depends on the physical structure stability of the pipettor, which cannot or is extremely difficult to adjust. The closer the value is to 0, the better the accuracy, and the higher the precision.

Au-Mate 96 fully automatic liquid handling workstation, measured accuracy and precision values of different specifications of pipetting blocks

Specification of Pipettor: 1-20 μL

Test Point | Number of Tests | Average Value | Accuracy | Precision |

1 | 2 | 3 | 4 | 5 |

1µL | 94.44 | 96.54 | 96.84 | 97.76 | 92.34 | 95.58 | -0.43% | 2.28% |

2µL | 189.40 | 189.18 | 188.08 | 190.26 | 190.06 | 189.40 | -1.36% | 0.45% |

10µL | 960.10 | 960.90 | 959.40 | 957.90 | 957.80 | 959.22 | -0.08% | 0.14% |

20µL | 1903.00 | 1909.24 | 1900.30 | 1900.40 | 1902.02 | 1902.99 | -0.89% | 0.19% |

Specification of Pipettor: 5-200 μL

Test Point | Number of Tests | Average Value | Accuracy | Precision |

1 | 2 | 3 | 4 | 5 |

5µL | 475.00 | 476.60 | 477.40 | 475.30 | 476.80 | 476.22 | -0.79% | 0.22% |

20µL | 1914.16 | 1923.20 | 1920.50 | 1918.40 | 1920.80 | 1919.41 | -0.03% | 0.18% |

100µL | 9574.44 | 9564.70 | 9568.60 | 9570.50 | 9566.40 | 9568.93 | -0.32% | 0.04% |

200µL | 19160.70 | 19147.50 | 19168.60 | 19159.40 | 19152.80 | 19157.80 | -0.22% | 0.04% |

Specification of Pipettor:100-1000 μL

Test Point | Number of Tests | Average Value | Accuracy | Precision |

1 | 2 | 3 | 4 | 5 |

100µL | 9624.80 | 9602.54 | 9590.00 | 9598.22 | 9610.98 | 9605.31 | 0.06% | 0.14% |

500µL | 47695.18 | 47625.84 | 47712.44 | 47702.14 | 47688.50 | 47684.82 | -0.66% | 0.07% |

1000µL | 95647.70 | 95622.10 | 95656.30 | 95612.40 | 95672.20 | 95642.14 | -0.37% | 0.03% |

Note: The measured value is obtained from 96-channel pipettor

ALLSHENG self-developed Au-Mate 96 series fully automatic liquid handling workstation can achieve efficient and accurate pipetting operations, including single column, multi column, and whole plate pipetting of 96 / 384 cell culture plates, gradient dilution within and between plates, blow mixing, magnetic bead separation, and other functions. The whole process automation of program editing helps you achieve more efficient and stable high-throughput drug screening experiments at the cellular level.

Reference:

1. Progress in the Application of High throughput Screening Technology in Drug Discovery -- Chinese Journal of Pharmacy, Issue 4

2. Cell-Based Drug Screening Technology - Beijing Abace

Biological Sample Preparation

Biological Sample Preparation

Life Science Detection Products

Life Science Detection Products

POCT Detection & Reagent

POCT Detection & Reagent

Automation & Liquid Handling

Automation & Liquid Handling

Laboratory Instrument

Laboratory Instrument

Reagent & Consumable

Reagent & Consumable

Others

Others

OEM/ODM

OEM/ODM

Release time:2023-11-02

Release time:2023-11-02

Source:

Source:

Pageviews:3008

Pageviews:3008

+ 86 571-88859758

+ 86 571-88859758 sales@allsheng.com

sales@allsheng.com