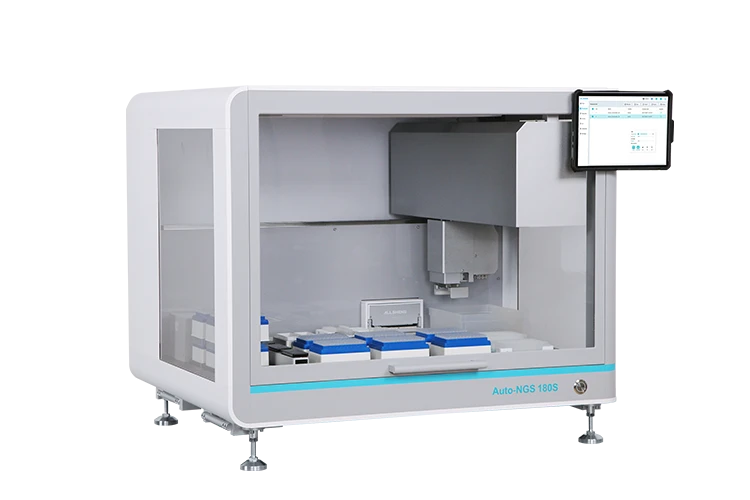

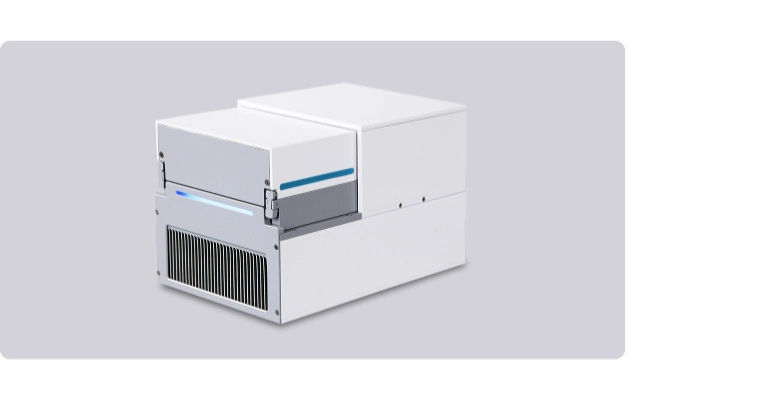

Overview

Key Configuration

Plate Layout

24-Channel Pipettor

-

Pipetting range 1~200 μL, 24-channel fixed spacing pipettor can be used as 24 channels, 16 channels, 8 channels, single channel or any channel.

Pipetting range 1~200 μL, 24-channel fixed spacing pipettor can be used as 24 channels, 16 channels, 8 channels, single channel or any channel.

Fluorometer

-

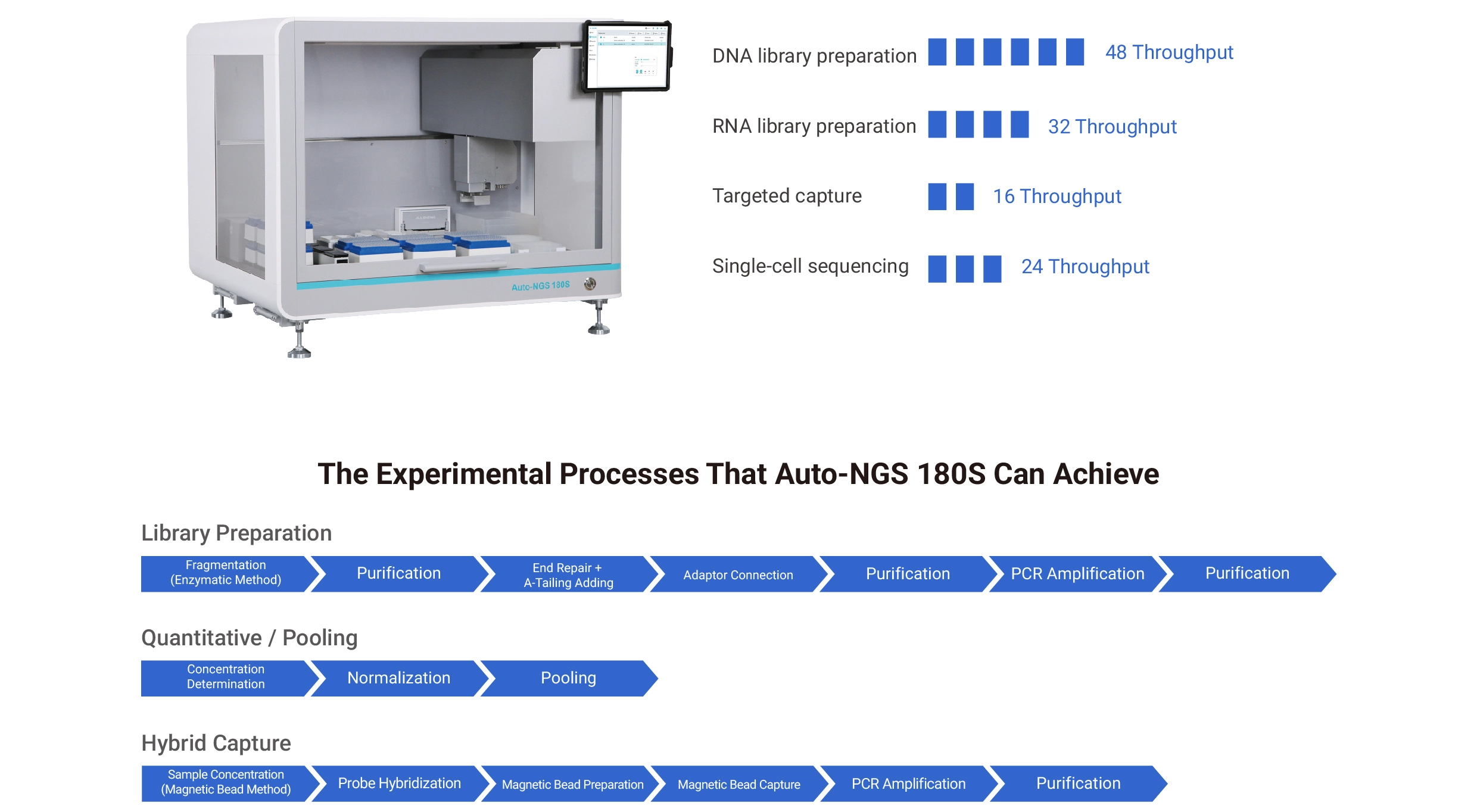

The fluorometer block, independently developed and designed by Allsheng, meets concentration measurement requirements during library preparation. With software, it can realize automated normalization, pooling, etc.24-well design, can test 24 samples simultaneously.Lowest detection limit down to 0.02 ng/μL (dsDNA).Accurate quantitation and high accuracy with only 2-20 μL samples.

The fluorometer block, independently developed and designed by Allsheng, meets concentration measurement requirements during library preparation. With software, it can realize automated normalization, pooling, etc.24-well design, can test 24 samples simultaneously.Lowest detection limit down to 0.02 ng/μL (dsDNA).Accurate quantitation and high accuracy with only 2-20 μL samples.

PCR Amplification Block

-

Block temperature control range: 4 °C ~ 99 °C, the temperature range of the thermo lid is 30 °C~120 °CTemperature precision: ≤0.2 °C @55 °C, temperature accuracy ≤±0.3 °C @55 °CTemperature uniformity: ≤0.7 °C (@55 °C, 72 °C)

Block temperature control range: 4 °C ~ 99 °C, the temperature range of the thermo lid is 30 °C~120 °CTemperature precision: ≤0.2 °C @55 °C, temperature accuracy ≤±0.3 °C @55 °CTemperature uniformity: ≤0.7 °C (@55 °C, 72 °C)

Thermo Shaker Incubator Block

-

A thermo shaker incubator applied to Allsheng automation workstation. The incubator can be used for heating, incubation and mixing of deepwell plates. The high-precision zero positioning function ensures the safe pipetting by the pipettor, with the anti-vibration technology and 2D motion control.Temperature range: 30 °C~105 °CAmplitude: 2 mm, max speed: 3000 rpm

A thermo shaker incubator applied to Allsheng automation workstation. The incubator can be used for heating, incubation and mixing of deepwell plates. The high-precision zero positioning function ensures the safe pipetting by the pipettor, with the anti-vibration technology and 2D motion control.Temperature range: 30 °C~105 °CAmplitude: 2 mm, max speed: 3000 rpm

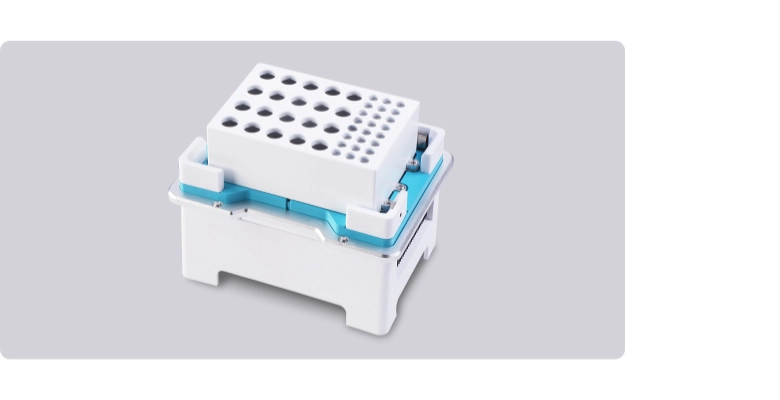

Temperature Control Block

-

Can be freely set at 4~105 °C. It's the standard temperature control block of NGS series. According to the usages, bock adapters can be customized to meet different consumables requirements.Temperature accuracy: ≤1 °CTemperature uniformity: ≤1 °C, @55 °C

Can be freely set at 4~105 °C. It's the standard temperature control block of NGS series. According to the usages, bock adapters can be customized to meet different consumables requirements.Temperature accuracy: ≤1 °CTemperature uniformity: ≤1 °C, @55 °C

-

-

-

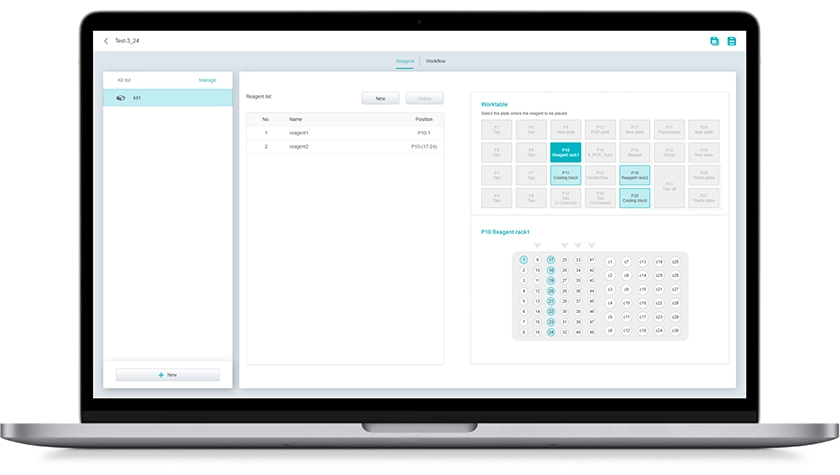

1Simple Reagent InputFree selection of well positions, and support for pre-filled reagents

-

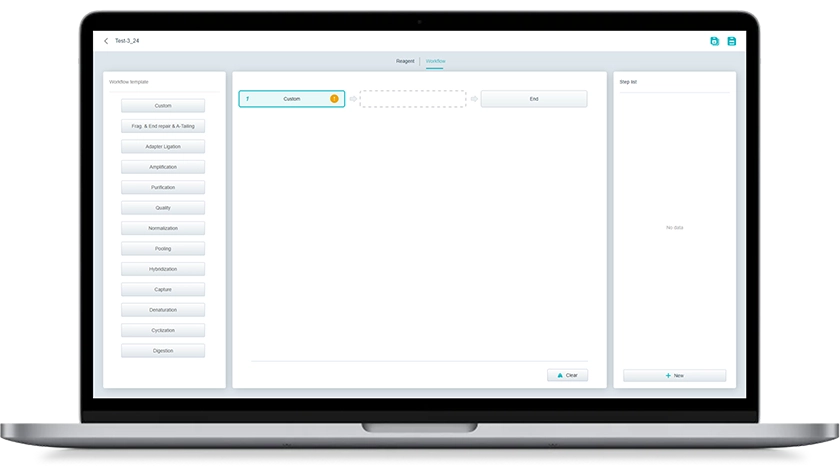

2Clear Software LogicThe cartridge running framework is completed through drag and drop operations

-

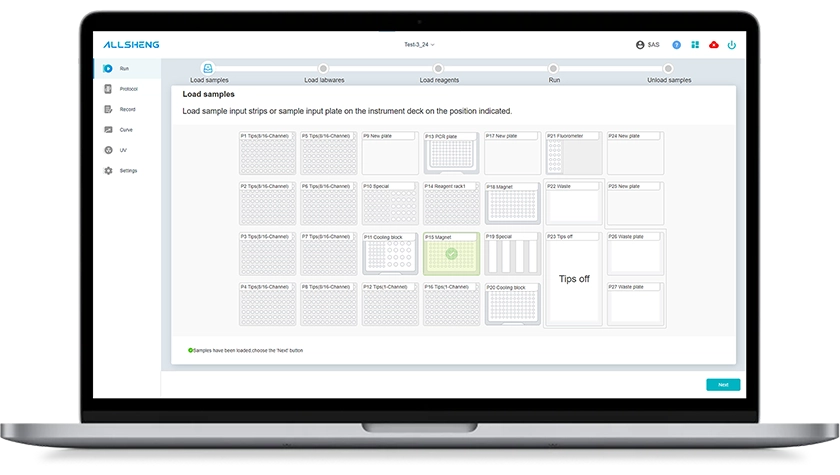

3Detailed Operation GuidanceFollow the software prompts to place consumables in order to run the program

-

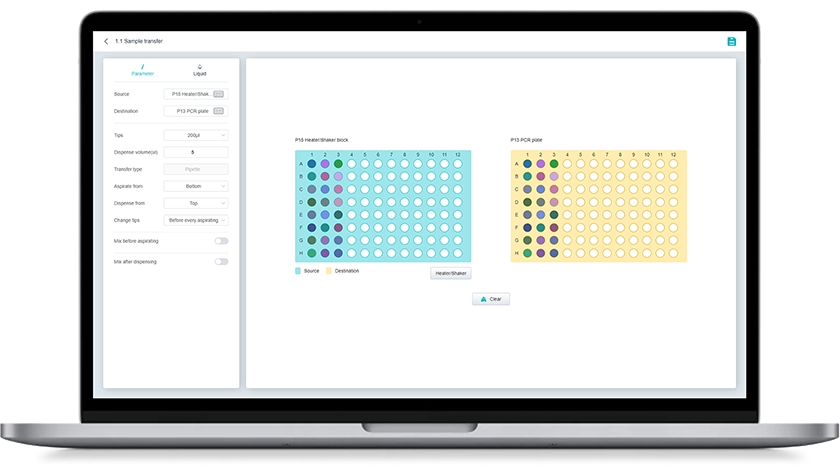

4Graphical Step EditingEasy to get started, with built-in multiple liquid parameters matching precise pipetting requirements

-

Model | ||||

Throughput | 24 | 24 | 48 | 96 |

Pipettor | 8-channel | 8-channel | 24-channel | 24-channel |

Pipetting range | 1-200 μL | 1-200 μL | 1-200 μL | 1-200 μL |

Shaking block | / | / | √ | √ |

Quality control block | / | √ | √ | √ |

PCR block | √ | √ | √ | √ |

Dimension (W×D×H) | 799×767×775 mm | 800×774×775 mm | 980×793×830 mm | 1420×790×800 mm |

Note: 48 refers to the instrument's maximum throughput

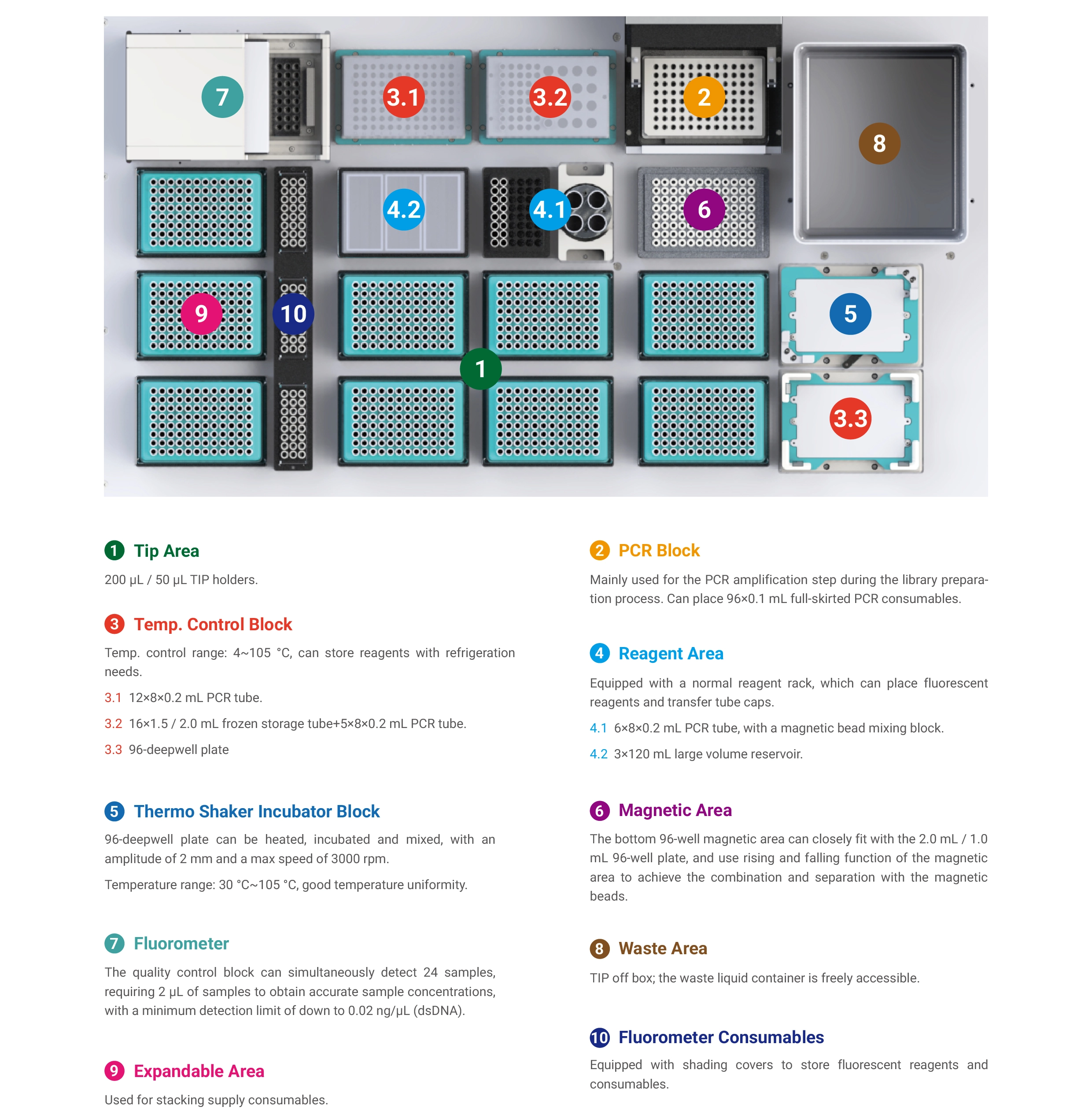

| Model | Auto-NGS 180S |

| Throughput | 8~24 |

| Plate number | Up to 9 tip boxes, including 5 single-layer tip tiles and 2 double-layer tip tiles |

| Pipettor | 200 μL; 24-channel (can be used as a single channel) |

| Pipettor | Minimum detection volume: 20 μL |

| Pipetting range | 1~200 μL |

| Pipetting precision (CV) | 1 μL≤8 %; 2 μL≤5 %; 5 μL≤4 %; 20 μL≤1 %; 100 μL≤1 %; 200 μL≤1 % |

| Pipetting accuracy (A) | 1 μL≤±10 %; 2 μL≤±8 %; 5 μL≤±4 %; 20 μL≤±2 %; 100 μL≤±1 %; 200 μL≤±1 % |

| Cooling block | 2 cooling blocks, can be used to save cold-storage reagents |

| Cooling block | Temperature control range: 4~105 °C |

Cooling block | Temperature control accuracy: ≤1 °C |

| Cooling block | Temperature control uniformity: ≤1 °C @55 °C |

| Heating mixing block | 1 heating mixing block |

| Heating mixing block | Temperature control range: 30 °C~105 °C |

| Heating mixing block | Temperature control accuracy: ±0.5 °C |

| Heating mixing block | Temperature uniformity: ≤1 °C @55 °C |

| Thermal cycling block | Temperature control range: thermo lid: 30 °C~120 °C; block: 4 °C~99 °C |

| Thermal cycling block | Uniformity: ≤0.7 °C |

| Thermal cycling block | Accuracy: ≤±0.3 °C |

| Fluorescence detection | Repeatability: CV ≤1.5 % |

| Fluorescence detection | Inter-well repeatability: CV ≤10 % (0.4 ng ≤ Total dsDNA<1 ng) |

| Fluorescence detection | Inter-well repeatability: CV ≤5 % (1 ng ≤ Total dsDNA<2 ng) |

| Fluorescence detection | Inter-well repeatability: CV ≤2 % (Total dsDNA >2 ng) |

| Fluorescence detection | Accuracy: ≤15 % (0.4 ng, compared to Qubit) |

| Magnetic plate | 96-well annular magnetic plate |

| Gripper | Yes |

| Consumable stacking mode | Consumable stack |

| UV sterilization | Equipped with UV sterilization lamp, HEPA device |

| Instrument port | USB port |

| Information management | External scanner for entering sample / reagent information |

| Information management | Expandable LIS system connection |

| Information management | Expandable cloud database connection |

| Operating environment | Temperature requirement: 15 °C~25 °C; Relative humidity: ≤80 % |

| Power supply | 100~240 V, 50 / 60 Hz, rated power 1700 VA |

| Dimension (W×D×H) mm | 1085×795×840 mm |

| Code | Product description |

| A5-27060-00 | Auto-NGS 180S automated NGS library preparation workstation |

Product Information

Article Application